-

-

CT Non-Vacuum High- and Low-Temperature Probe Station

View Details

View Details

-

CRX Series Closed-Loop Vacuum Cryogenic Probe Station

View Details

View Details

-

M001 Vacuum High- and Low-Temperature Probe Station

View Details

View Details

-

M002 Vacuum High- and Low-Temperature Probe Station

View Details

View Details

-

CRX-SM Cryogenic Superconducting Vacuum Probe Station

View Details

View Details

-

EMMI Photon Micro-Leakage Analysis Probe Station

View Details

View Details

Products

-

-

-

-

-

Iron-Based Piezoelectric Analyzer TF Analyzer 3000

Testing instrument

- Description

- Parameters

- Download

- Video

-

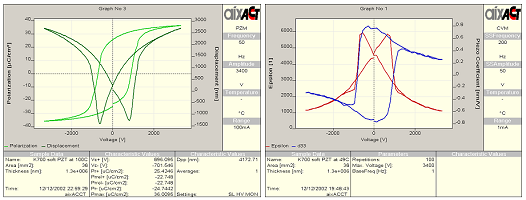

Voltage Electroanalytical Analyzer TF Analyzer 3000

The TF ANALYZER 3000E is a highly scalable, high-speed modular ferroelectric and piezoelectric analyzer equipped with comprehensive testing capabilities for all fundamental properties of ferroelectric, piezoelectric, and pyroelectric materials. It can be seamlessly integrated with micro-displacement sensors such as laser interferometers and SPM scanning probe microscopes, making it an ideal tool for research in diverse fields—including various ferro-/piezo-/pyroelectric thin films, thick films, bulk materials, electronic ceramics, as well as ferroelectric sensors, actuators, and memory devices.

The modularly designed TF Analyzer 3000 boasts exceptional scalability.

- FE Module – Ferroelectric Standard Testing;

- MR Module – Testing of Magnetoresistive and Ferromagnetic Materials;

- RX Module – Relaxation Current Testing;

- DR Module - Self-Discharge Test.

-

Test basic unit: Includes a fully integrated dedicated computer host along with test boards, operational amplifiers, data processing units, and more. It also features the Windows 7 operating system and specialized testing software for ferroelectric analyzers.

FE Module Standard Testing Function:

- Dynamic Hysteresis: Testing frequency for dynamic hysteresis loops (Enhanced FE module: 250 kHz; High-speed Enhanced FE module: 1 MHz);

- Static Hysteresis Loop Test;

- PUND Pulse Testing;

- Fatigue Testing;

- Retention: Holding Power;

- Imprint: Traces;

- Leakage current test;

- Thermo Measurement Variable-Temperature Testing Function.

Optional test functions for the FE module:

- C-V curve: Capacitance-Voltage Curve;

- Piezo Measurement: Piezoelectric Performance Testing;

- Pyroelectric Measurement: Thermal Emission Property Testing;

- In-situ Compensation;

- DLCC Dynamic Leakage Current Compensation Function;

- Impedance Measurement – Impedance Testing (available only for the High-Speed Enhanced version).

Technical Note:

- Voltage range: ±25 V (optional additional high-voltage amplifiers can extend up to ±10 kV);

- Electrostrictive frequency: Enhanced FE module – 250 kHz; High-speed enhanced FE module – 1 MHz.

- Minimum pulse width: 50 ns;

- Minimum rise time: 10 ns;

- Maximum clock frequency: 16 MHz;

- Current amplification range: 1 pA to 1 A;

- Maximum load capacitance: 1 nF;

- Output current peak: ±1 A.

Scalable components:

High-voltage amplifiers, laser interferometers, AFMs, temperature controllers, thin-film probe-based heating and cooling stages, variable-temperature bulk sample holders, bulk furnaces for temperature control, thin-film E31 testing platforms, superconducting magnets, PPMS systems, impedance analyzers, and more.

The MR module is used to study magnetoresistance and ferromagnetic materials.

This module provides continuous current excitation and testing, with voltage drops across the sample measured using a high-precision four-point method.

The RX module is designed to study polarization and depolarization currents in dielectric and ferroelectric materials—specifically, the current response following an applied voltage step.

This test can separate the material's relaxation current from the leakage current, and it also allows for the recording of both the polarization response current and the depolarization response current.

The DR module is used to study the self-leakage properties of dielectric materials. 。

Since the test conditions closely mimic real-world scenarios, this approach makes it easy to evaluate the suitability of materials for use in DRAM.

For industrial applications, the TF Analyzer 3000 offers 256 automated test channels, significantly expanding the instrument's testing capabilities. 。

All of the above modules can be selected individually or combined freely, depending on your testing needs and research focus.